Какъв е принципът зад електричните актуатори

1. Електродвигателът

Електрическият мотор е сърцето на актуатора. Той преобразува elektricheska енергия в механична енергия. Има два основни типа мотори, използвани в електрическите актуатори:

- DC Мотори: Тези мотори се пита от пряка ток и се отличават с простотата си и лесното им управление. Често се използват в приложения, изискващи точен контрол над скоростта и позицията.

- AC Мотори: Тези мотори се пита от алтернативен ток и обикновено се използват в приложения, изискващи висока мощност и ефективност. Те са по-сложни за управление в сравнение с DC моторите.

2. Механизъм за преобразуване

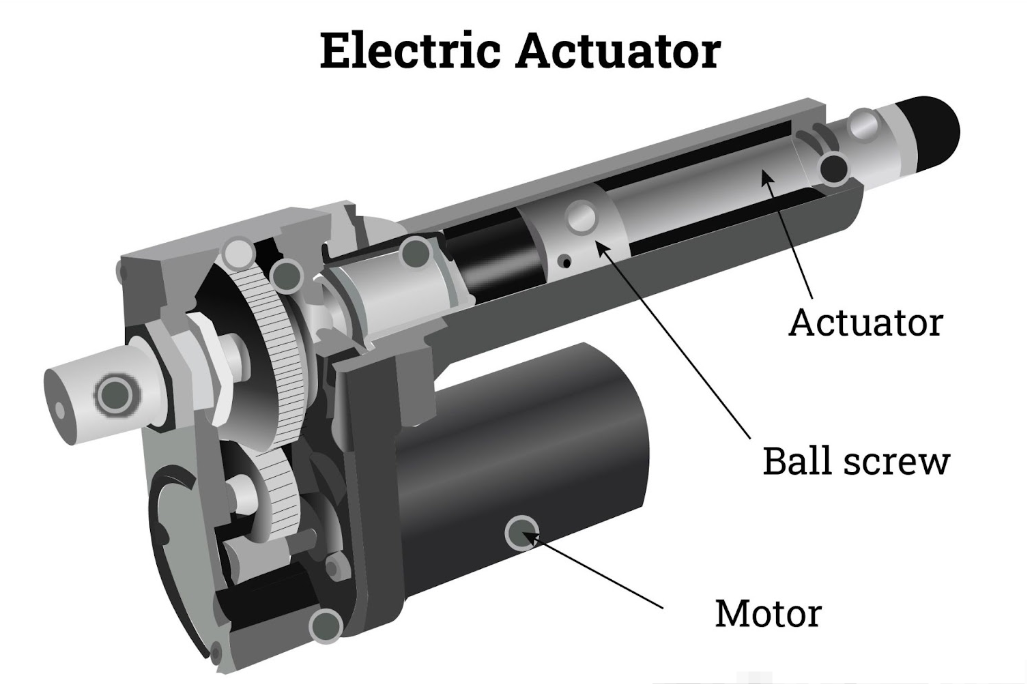

Механизъмът за преобразуване превръща въртящото движение на мотора в желания вид движение:

- Механизъм с ръбовит винт: В линейните актуатори се използва ръбовит винт (или топкестен винт) за преобразуване на въртящото движение в линейно движение. Винтът се върти, причинявайки гайка да се движи по дължината му, което, във своя ред, движи изходната ос на актуатора.

- Механизъм за превод: В ротационните актуатори често се използват зъбати колела, за да се регулират скоростта и моментът на изхода на мотора. Ротационното движение на мотора се използва директно, за да се върти вала или друг механизъм.

3. Система за управление

Системата за управление управлява работата на актуатора. Тя интерпретира входящите сигнали и коригира движението на актуатора съответно:

- Модулация на импулса по ширина (PWM): Тази техника контролира скоростта на мотора чрез промяна на ширината на импулсите в импулсния поток. Използва се често в DC мотори.

- Контрол на напрежението: Чрез промяна на напрежението, подадено към мотора, може да се контролира скоростта и посоката на актуатора.

- Цикли на тока: В някои приложения се използват цикли на тока за точен контрол върху позицията и скоростта на актуатора.

4. Механизъм за обратна връзка

Механизмите за обратна връзка са от ключово значение за приложенията, изискващи висока прецизност и повторяемост:

- Енкодери: Тези устройства предоставят обратна връзка относно позицията и скоростта на актуатора. Те могат да бъдат оптични, магнитни или механични.

- Потенциометри: Тези са променливи резистори, които дават обратна връзка за позицията на актуатора. Те са по-прости и по-евтини от енкодерите, но предлагат по-ниска точност.

5. Извор на електроенергия

Изворът на електроенергия осигурява необходимата електрическа енергия за актуатора. Той може да бъде прост батерия или по-сложен извор на електроенергия, в зависимост от приложението:

- Батерия: Приложените приложения често използват батерии за да задават енергия на актуатора.

- Източник на електроенергия: За стационарни приложения, източникът на електроенергия преобразува алтернативното напрежение от мрежата в необходимото постоянн постоянен ток за актуатора.

Приложения на електрически актуатори

Електрическите актуатори се използват в широк спектър от приложения поради техния универсалитет и точност:

- Роботика: Електрическите актуатори се използват за контролиране на движението на роботични ръце и други компоненти.

- Автомобилна индустрия: Те се използват в различни автомобилни системи, като стъклоподемници, регулиране на седалките и контрол на дроселната заслонка.

- Авиация: Електрическите актуатори се използват в системите за управление на самолети, като например спойлери и приземни апаратури.

- Производство: Те се използват в автоматизираното оборудване и линии заmontажа за контрол на движението на части и инструменти.

Електрическите актуатори предлагат няколко предимства, включително точен контрол, лесна интеграция с електронните системи и възможността да работят в широк диапазон от среди. Те са основен компонент в съвременните системи за автоматизация и управление.HCIC е професионален производител на хидравлически системи, главно ангажиран с проектиране, производство, инсталиране, преобразуване, тестове на хидравлически системи и продажби на хидравлически компоненти под марка, както и технически услуги. Надяваме се, че нашите продукти могат да помогнат за намаление на вашите разходи и подобряване на качеството. За повече подробности ни пишете на "[email protected]" или търсете в Google "HCIC hydraulic"

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

KA

KA