Hydraulic cylinder sizing in such machinery - bulldozers and excavators for example, is an important aspect of the hydraulic world. Choosing the right hydraulic cylinder size for your equipment is more than just a chore; it's an important step in avoiding potential problems that can cause downtime and repair expenses to skyrocket. So, to help you with the task here is a comprehensive guide for you on how do hydraulic cylinder sizing and some important tips, mistake which need to avoid while performing it besides the impacts of wrong sized hydraulics cylinders onto your machinery.

How to Size a Hydraulic Cylinder

Understand the Force Requirements: The first hydraulic cylinder sizing consideration is how much force your equipment must exert. The equipment's manual or a hydraulics specialist is generally an optimal source for this information.

Stroke Length: The stroke length of a hydraulic cylinder is the distance it needs to travel in order to complete its job. Not choosing the correct stroke length in a cylinder can lead to problems such as bottoming out or damage to equipment.

Think about Travel Speed: Another essential factor in sizing is the speed that you will need to be able to move the cylinder at. The proper selection of the cylinder size ensures that your system runs at the right speed to get tested and calibrated results.

Choosing The Suitable Size Of A Hydraulic Cylinder In More Detail

When sizing a new hydraulic cylinder, you must choose your size wisely by carefully analyzing the following things:

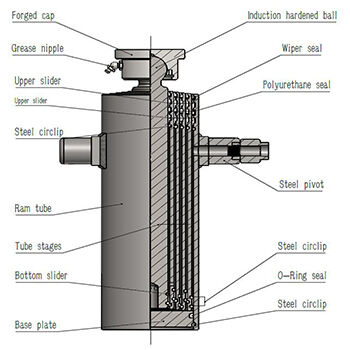

Cylinder Bore Size: Different bore sizes of the cylinder influences amount of force, a particular type can produce. The BIGGER. the bore, the GREATER is its BLOWING capacity!

Rod Diameter: The rod diameter gets selected based on avoiding bending and cylinder failure, sustaining the structural life of it.

Stage length: The stroke period of a cylinder is the furthest out and in limits that your new jack requires!

Operating Pressure: The operating pressure from the cylinder restricts how hard it for this to exert making corresponding the particular pressures needs in between your system and also actuator important.

Top Misconceptions with Hydraulic Cylinder Sizing

Hydraulic cylinder sizing errors can cause devastating impacts on your machinery, resulting in expensive consequences. AuthorTo avoid these traps, remember:

Don't Super-Size:Getting a cylinder that is too big can decrease equipment efficiency and might even break something.

Oversizing A Cylinder: Choosing a cylinder too small can cause equipment failure and decreased machine speeds.

Right Length of Stroke: Picking a stroke length that is wound up as too long or unreasonably short can result in instrument loads and poorly working arrangements.

5 Key Points for Hydraulic Cylinder Sizing

Hydraulic cylinder sizing also matters, so consider these factors to keep your new cylinder operating at peak performance over the years.

Force: sizing the cylinder to meet force requirements is crucial for proper machine performance.

Temperature: The system operating temperature affects the hydraulic cylinder's performance, and that means a cooler or transformer in action needs to handle some heat.

Eco- Factors: The surroundings in which the machine is working affects, to a fantastic extent on what form of equipment and protection required by using would be hydraulic cylinder

Pressure Ratings - At the time of ordering, make sure that the cylinder selected is able to work with operational pressure so as not run into any trouble later on.

How Incorrect Sizing of Hydraulic Cylinder can Affect Equipment

Selecting the right size hydraulic cylinder is crucial to your machine... while choosing one of the wrong sizes can destroy it far quicker and in a variety more dramatic ways;

Decreased Efficiency: Over- or under-sized cylinders can lower equipment efficiency, and as a result increase work-load.

Damages to equipment:Using a cylinder of an incorrect size may lead you into damaging it, as well as other components.

Costly Downtime, Repairs and Cylinder Replacements: Using the wrong size of cylinder incorrectly sized can lead to unexpected downtime as well repairs or replacements that come with these serialized bottoms-line hits.

This emphasizes why hydraulic cylinder sizing is so critical if you want your machinery to function properly. This detailed guide will provide you with the know-how necessary to determine hydraulic cylinder sizing, ensuring your equipment stays safe and productive.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

KA

KA