What are Hydraulic Actuators - A hydraulic actuator is a component of hydro-mechanical transmission that is used to transfer, maintain and control energy through use of pressurized fluid. It is widely used in the manufacturing sectors, construction industries as well as for transportation systems. In this post, we will get into the nitty-gritty of hydraulic actuators and what their advantages and disadvantages are to help you make an educated decision on which one is the best for your application.

Types of Hydraulic Actuators

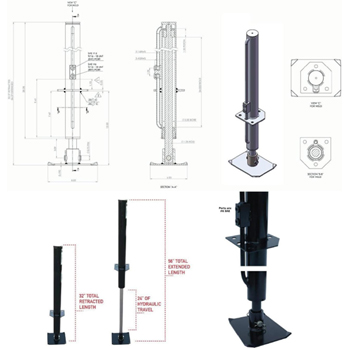

Hydraulic actuators come in two primary types: hydraulic cylinders and hydraulic motors. Hydraulic cylinders provide linear motion, while hydraulic motors into rotary. Whilst both are mechanically significantly different in terms of their operation, they share the common fundamental principle that hydraulic pressure is used to provide motion

The Principle of Operation in Hydraulic Actuators

These units are made up of: An oil reservoir A pump Valves And a cylinder or motor (2) It is a pump that creates pressure in the hydraulic oil to flow through the valves and then directed into cylinder or motor. When the fluid in a hydraulic system is pressurize it move (exerts pressure) against another piston inside a cylinder to make that one start moving. This movement can be used for linear motion to move large loads or machine pieces, as well as rotation of a shaft.

Choose the Perfect Actuator for Your Application

Several factors must be taken into account when choosing the right hydraulic actuator. The type of motion required (linear or rotary) --> ap- plied. Next to consider is how big the load or force necessary must be. Hydraulic cylinders are used for heavier loads while hydraulic motors would be suitable on lighter applications. Finally, it is necessary to consider the speed and accuracy needs while outlining hydraulic cylinders pointing that when compared with a standard electric motor calendering machine a hydraulic cylinder provides more rapidity for this kind of appliance.

Pros and Cons Of Hydraulic Actuators

The Hydraulic Actuators have multiple advantages over other actuators available. These have a quick dynamic response time that offer up to five times the high power density of electric, pneumatic or mechanical actuators. In addition, they are known for being dependable and long lasting as these units have a very long service life with hardly any maintenance.

Nevertheless, one should also consider the drawbacks of hydraulic actuators. They can produce noise and vibrations, which may be problematic in particular applications. Now, the hydraulic fluid reservoir is claimed to chew up precious room and weight in your system.

Typical Uses for Hydraulic Actuators in Industry

Hydraulic actuators are widely used in a range of industries due to their numerous advantages. These hydraulic cylinders are used in construction machinery to lift and move heavy things like crane arms or excavator buckets. Hydraulic motors are used within transportation systems to power industrial machinery - conveyors and pumps, e. g.. In addition the hydraulic actuators are widely employed in lifting and rotating movements, a part of material handling systems for lifts or conveyor operations.

In summary, hydraulic actuators play a critical role in many industrial and manufacturing processes. This unique combination of outstanding power densities, reliability and durability makes our systems ideal for a wide range applictions. To really know which is best for your particular situation you need to fully understand how hydraulic actuators work, what their benefits are and also what the drawbacks can be.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

KA

KA