Sistemele hidraulice asigură că majoritatea mașinilor de astăzi funcționează neted și fără niciun incident. Ele sunt fundamentale în totul, de la cele mai mici unelte portabile până la mașinarii mari, cum ar fi echipamentele de construcții și aeronavele. Huachen: Este o companie specializată în producerea acestor sisteme hidraulice. Aceasta creează sisteme hidraulice mari și utile pentru diferite tipuri de servicii. Vom intra adânc în subiectul sistemelor hidraulice, vom explora ce sunt acestea și cum au fost concepute, împreună cu principiile de întreținere care se aplică, dar și selecția componentelor și practicile bune pentru a le face să performeze și mai bine.

Ce sunt Sistemele Hidraulice?

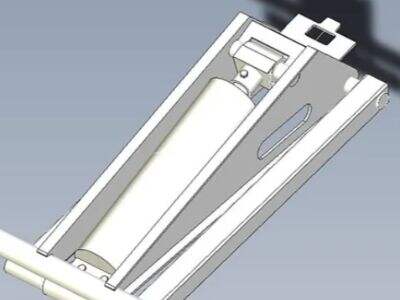

Cred că sistemele hidraulice sunt grozave. Acest lucru se datorează faptului că, în loc de motoare și înghemături și alte chestii mecanice grozave de genul acela, ele folosesc ulei sau apă (care ambele știm că nu este destinate să facă altceva decât să umple spațiu în râuri). Funcționează în aceeași manieră prin producerea unei presiuni care apoi împinge lichidul prin tuburi, conducte, valvoide și cilindri (direct). Modul în care acest lucru este realizat, așa cum s-ar putea presupune din fotografie la titlu de mai sus, implică ca lichidul sub presiune să genereze mișcare prin împinerea cilindrilor și pistonilor. Sistemul hidraulic poate fi controlat fie prin intermediul presiunii, fie prin volumul de lichid care este propulsat prin el. Acest lucru înseamnă simplu că inginerii pot schimba ceea ce fac mașinile doar prin configurarea unui sistem hidraulic diferit.

Proiectarea Sistemelor Hidraulice

Inginerii sunt nevoiți să ia în considerare multe aspecte atunci când proiectează un sistem hidraulic. Trebuie să poată să decidă mai întâi cât de greu este ceea ce trebuie să ridice sau să mute. Acest lucru se numește sarcină. Apoi, ei determină viteza la care un sistem trebuie să ruleze. În multe situații, un element crucial de luat în considerare este viteza, așa cum vei vedea în construcții sau producție. De asemenea, trebuie să ia în considerare funcționarea sistemului la temperatura și presiunea potrivite. În plus, rezistența componentelor merită să fie ținută minte: acestea trebuie să fie suficient de rezistente încât să se strice doar o dată la câteva ani.

Costul este altceva pe care oamenii de știință o au în vedere când proiectează un sistem. Ei vor să se asigure că acesta este accesibil financiar și în același timp suficient de eficient. Reparatibilitatea unui sistem atunci când apar eșecuri este de asemenea ceva de luat în considerare.Și, în sfârșit, există siguranța. Inginerii trebuie să se asigure că un sistem hidraulic este sigur pentru toată lumea care va folosi.

Menținerea Sistemului Hidraulic

Sistemele hidraulice, la fel ca orice altă mașinărie, pot să întâlnească probleme specifice de la timp la timp. Uneori acestea pot apărea din cauza îmbătrânirii sistemului sau din cauza unei instalări inițiale defectuoase. Diagnosticarea sistemelor hidraulice implică determinarea ceea ce nu funcționează corect. Problemele sunt adesea cauzate de scurgeri ale conductelor care provoacă pierderea presiunii sau eșuarea cilindrelor care pot împiedica funcționarea sistemului. Când inginerii identifică problema, trebuie să petreacă mult timp hotărind dacă o piesă avariată ar trebui reparată sau înlocuită complet.

Sistemele hidraulice trebuie menținute, ceea ce este necesar pentru a le asigura îngrijirea. Altfel, pot cauza probleme mai târziu. Filtrele, conductele, pompele și valorile sunt unele dintre piesele care trebuie verificate regulat. Prin urmare, menținerea acestor componente în stare bună poate contribui la garantarea faptului că sistemul va funcționa fără niciun obstacol timp de mulți ani.

Selectați Părțile Hidraulice Corespunzătoare

Sistemele hidraulice au nevoie de piese potrivite pentru a fi eficiente. Acestea ar trebui să aibă capacitatea de a transporta greutatea specificată și să continue să funcționeze la viteza necesară pentru a efectua anumite acțiuni. Majoritatea pieselor necesită control al temperaturii și presiunii, dar nu toate piesele pot funcționa sub aceleași condiții; este important să se înțeleagă cu ce este compatibilă fiecare parte. Dacă uleiul sau lichidul folosit în sistemul tau este diferit de cel pe care materialul de sigiliere reciprocant îl acceptă, acest lucru poate provoca uzurare excesivă. Acest lucru poate include cilindri, pompe și robinete, printre alte componente hidraulice comune. Piese mai bune care funcționează împreună vor face întregul sistem mai eficient.

Indicații Prețioase Pentru un Sistem Hidraulic

Hidraulica poate, știm cu KTM și cu picioarele Atkinson datorită utilizării lor a unui suspensie hibridă dublu trapez clever, despre care alți postatori au menționat deja. Un motor cu viteza variabilă este un exemplu de metodă prin care se poate realiza acest lucru. Acest lucru permite ajustarea fluxului de intrare sau a presiunii lichidului în funcție de câtă sarcină acela sistem lucrează la un moment dat. O altă soluție eficientă este să se creeze un model pe computer al sistemului hidraulic înainte ca acesta să fie construit. Inginerii pot modela diferite scenarii pentru a explora ce funcționează cel mai bine și pot schimba planul inițial.

Alte informații utile sunt aplicarea sistemelor de monitorizare la distanță pentru urmărire oportună a comportamentului sistemului hidraulic. Aceasta permite răspunsuri mai rapide în cazul apariției unei probleme. Este de asemenea utilă implementarea mentenânței predictive care inspectează posibilele probleme înainte ca o defectare majoră să apară. În sfârșit, printr-o pregătire adecvată și prin respectarea protocoalelor de siguranță, toată lumea care utilizează acest sistem hidraulic va putea să o facă în siguranță.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

KA

KA