Tổng quan

Tham số

Truy vấn

Sản phẩm liên quan

Giới thiệu sản phẩm:

Khám phá công nghệ tiên tiến của "Xi lanh Thủy lực cho Trạm Nén Rác," một giải pháp mạnh mẽ được thiết kế cho việc quản lý chất thải hiệu quả trong các hoạt động nén rác.

Ứng dụng sản phẩm:

Trạm Nén Rác: Được thiết kế riêng cho hiệu suất tối ưu trong quá trình nén chất thải.

Quản Lý Chất Thải: Lý tưởng cho các ứng dụng nén rác, đảm bảo xử lý và tiết kiệm không gian khi loại bỏ chất thải.

Đặc điểm của sản phẩm:

Hiệu Suất Nén Cao: Được thiết kế để cung cấp lực nén vượt trội, tối đa hóa việc nén chất thải.

Xây Dựng Bền Bỉ: Thiết kế robust đảm bảo độ bền và tin cậy trong môi trường quản lý chất thải khắc nghiệt.

Các Tùy Chọn Gắn Đa Dạng: Các cấu hình gắn linh hoạt cho sự tích hợp liền mạch vào nhiều hệ thống nén rác khác nhau.

Thông số Sản phẩm:

| Tham số | Giá trị |

| Đường kính lỗ khoan | 250 mm |

| Quãng đường | 1800 mm |

| Lực Định mức | 300 kN |

| Áp suất tối đa | 45 bar |

| Tốc độ piston | 0,8 m/s |

| Nhiệt độ làm việc | -10 đến 80°C |

| Loại Lắp Đặt | Giá gắn thanh nối |

| Đường kính thanh | 220 mm |

| Trọng lượng | 150 kg |

Giới thiệu công ty:

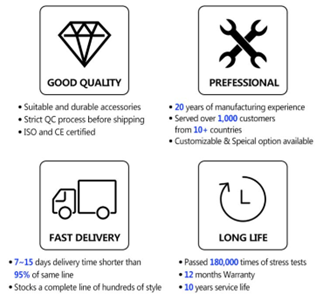

Giới thiệu HCIC (Hydraulic Cylinder Innovation Company), một nhà lãnh đạo được công nhận với 26 năm kinh nghiệm, chuyên cung cấp các giải pháp thủy lực để định nghĩa lại hiệu suất trong nhiều ngành công nghiệp khác nhau.

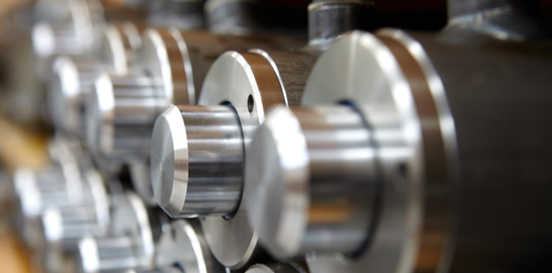

Các xi lanh dầu tiêu chuẩn của chúng tôi bao gồm xi lanh thủy lực thanh nối, xi lanh thủy lực máy đi bộ, xi lanh hàn, xi lanh xúc tuyết, xi lanh thuỷ lực telescop, xi lanh đổ chất thải, xi lanh thủy lực cho người cắt gỗ, xi lanh thủy lực cho máy xúc và xi lanh thủy lực nghiêng xẻng. Chúng tôi cũng có thể tùy chỉnh theo yêu cầu.

Sản phẩm của chúng tôi:

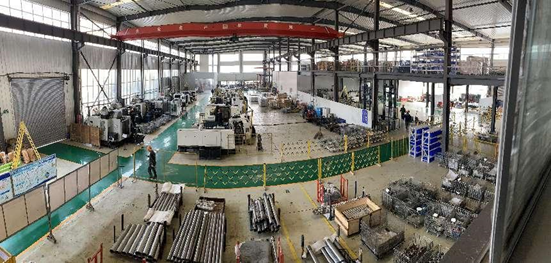

Nhà máy sản xuất hiện đại của chúng tôi đảm bảo việc sản xuất Xi lanh Thủy lực cho Trạm Nén Rác với độ chính xác và độ tin cậy cao.

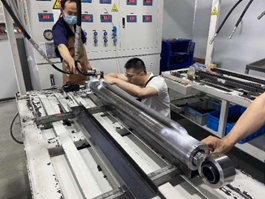

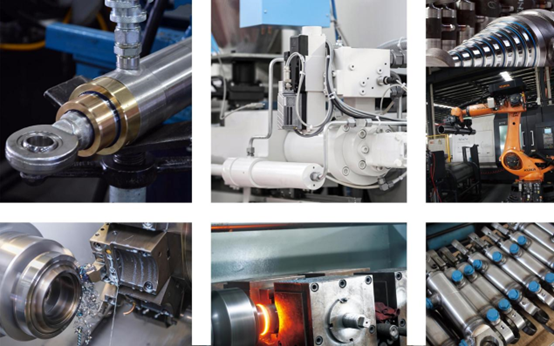

Chúng tôi có toàn bộ chuyên môn hàn cần thiết cho các giải pháp tùy chỉnh sản xuất. Chúng tôi chuyên về các thành phần hàn thép không gỉ và thép kết cấu cũng như các thiết kế phức tạp, bao gồm cả hàn thủ công và bằng robot. Thiết bị robot của chúng tôi xử lý một lượng lớn công việc hàn lặp đi lặp lại để đơn giản hóa sản xuất và đảm bảo chất lượng bền vững. Chúng tôi có toàn bộ chuyên môn hàn cần thiết cho các giải pháp tùy chỉnh sản xuất. Chúng tôi chuyên về các thành phần hàn thép không gỉ và thép kết cấu cũng như các thiết kế phức tạp, bao gồm cả hàn thủ công và bằng robot.

Dịch vụ của chúng tôi:

Giải Pháp Tùy Chỉnh: Hợp tác với chúng tôi để có các giải pháp thủy lực theo yêu cầu, đáp ứng các nhu cầu đặc thù của ứng dụng nén rác.

Hỗ Trợ Kỹ Thuật: Sử dụng chuyên môn kỹ thuật của chúng tôi để tích hợp liền mạch và đạt hiệu suất tối ưu cho xy-lanh thủy lực của chúng tôi.

Sự Hiện Diện Toàn Cầu: Được hưởng lợi từ mạng lưới toàn cầu của chúng tôi, đảm bảo giao hàng kịp thời và hỗ trợ toàn diện.

|

|||

|

|||

Những ưu điểm của chúng tôi:

Nén Hiệu Quả: Được thiết kế cho hiệu suất nén cao, tối ưu hóa quy trình nén rác thải.

Thiết Kế Bền Bỉ: Xây dựng chắc chắn đảm bảo tuổi thọ dài lâu, ngay cả trong môi trường thách thức của các trạm nén rác.

Lắp Đặt Đa Dạng: Các tùy chọn lắp đặt linh hoạt cho phép tích hợp dễ dàng vào nhiều hệ thống nén rác khác nhau.

FAQ (Các câu hỏi thường gặp):

Q: Phạm vi nhiệt độ làm việc được khuyến nghị cho xy-lanh thủy lực này tại các trạm nén rác là gì?

A: Xy-lanh được thiết kế để vận hành hiệu quả trong dải nhiệt độ từ -10 đến 80°C.

Q: Xy-lanh này có thể được tùy chỉnh cho các ứng dụng nén rác cụ thể không?

A: Hoàn toàn có thể, các xy-lanh thủy lực của chúng tôi rất linh hoạt, cho phép tùy chỉnh để đáp ứng yêu cầu độc đáo của các hệ thống nén rác khác nhau.

Logistics:

Trải nghiệm sự hiệu quả của hệ thống logistics của chúng tôi, đảm bảo giao hàng kịp thời các xi lanh thủy lực cho trạm nén rác, được thiết kế riêng để nâng cao hiệu suất hoạt động quản lý chất thải của bạn!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

KA

KA