What Is the Best Material for Hydraulic Cylinders

Hydraulic cylinders power a range of industries, from agriculture to mining to construction and aerospace. Because they must withstand immense pressure, the different materials they're constructed from are solid and durable.

Hence why, for the most part, hydraulic cylinders primarily consist of stainless steel, aluminum, bronze, and chrome. Of course, the exact combination of alloys and hydraulic cylinder materials varies based on the operating parameters.

Therefore, when it comes to the design of a hydraulic cylinder, there isn't an optimal alloy or material. Instead, a selection of commonly used materials is chosen to satisfy different requirements and prolong hydraulic oil life expectancy.

Regardless of what your hydraulic cylinder is made from, Cylinders, Inc. can repair anything!

What Are Hydraulic Cylinder Parts Made Of?

Below are the most commonly utilized materials used in cylinder servicing and production:

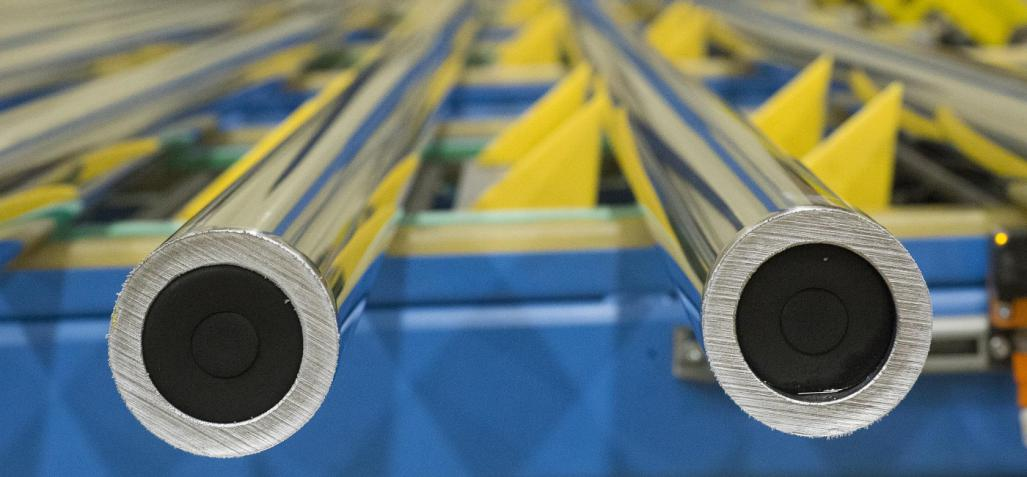

Hydraulic Cylinder Barrel

The barrel is a key component of a hydraulic cylinder, typically made from cold-rolled or honed seamless steel or carbon steel tubing. Cylinder tubes hold and contain the cylinder's pressure and house all parts essential for its functioning.

Glands & Pistons

The style of piston rods and glands is influenced by various design requirements, loading, and pressure. The standard material used for the barrel is high-tensile SAE C1026 or St52.3 cold-drawn tubes honed for increased seal life. Other piston rod options include 4140, aluminum, and stainless steel.

Wiper, Rod, and Piston Seals

Pressure characteristics, durability, operating, and environmental temperatures influence the size and type of rod seal and piston seal used. Materials utilized for a static seal can range from high-performance polyurethane and nitrile rubber to fluoro rubber, ethylene propylene diene, silicone, and resin-bonded fabric composite or polyester elastomer.

Shafts

Several shaft considerations are needed, such as speed, displacement requirements, retraction forces, loads, and corrosion resistance. Various materials are available, including chrome-plated, chrome-over stainless steel, nitrided, chrome-over-nickel, and high-strength alternatives.

Cylinder Mounts

Cylinder mounts are engineered to reduce the amount of friction and wear that would otherwise occur on rod seals and bearings. They are generally made of steel, carbon steel, and ductile iron, offering superior durability and shock absorption, effectively extending the seals' and bearings' lifespans.

Paint

Epoxy, polyurethane, and chromicoxide are the three most popular types of paint used to protect hydraulic cylinders. Epoxy paint is corrosion and wear-resistant. Polyurethane paint offers the same protection but is more flexible, whereas chromicoxide paint is preferable for high-pressure applications due to its hardness and wear resistance.

More Common Materials Used in Hydraulic Cylinders Other common materials used for a hydraulic cylinder service include:

Stainless steel 301: This high-strength enthusiastically offers excellent corrosion resistance and can be welded easily, making it ideal for cylinders and cylinder rods. Furthermore, it demonstrates remarkable ductility properties when cold worked;

Titanium alloy grade 01: The softest and most pliable type of pure titanium, Grade 01 has the highest form ability, consisting of 99% titanium, 0.2% iron, 0.18% oxygen, and trace amounts of other elements such as nitrogen, carbon, and hydrogen;

Low alloy steel: This alloy not only has superior strength, flexibility, toughness, weld ability, and fatigue resistance but is also light and corrosion-resistant. It maintains power and form ability even in extreme temperatures;

Cast iron grade 60-44-18: An iron alloy of 60% iron, 44% carbon, and 18% manganese with excellent tensile strength and abrasion resistance, mainly used for fasteners and valve components;

Nickel-chromium alloys: These alloys are ideal for situations where a high level of protection from oxidation and corrosion is necessary, including constructing hydraulic cylinders. They display excellent high-temperature strength and electrical resistible;

Chrome-plating: Chrome plating provides long-lasting hydraulic cylinder protection. It's corrosion-resistant and reduces friction, making it optimal for high-pressure applications;

Nitrite rubber: Great for use in hydraulic cylinders, nitrite rubber is resistant to oils, impermeable to gas, flexible, and able to withstand repeated flexing and abrasion;

Neoprene rubber: Due to its good physical properties, neoprene is often used in the seals for hydraulic cylinders and provides an excellent barrier to prevent the loss of hydraulic fluid or air. It is UV-resistant and can be easily sealed and welded using high-temperature vulcanization.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

KA

KA