How HCIC to proof test hydraulic cylinders before delivery

How HCIC to proof test hydraulic cylinders before delivery

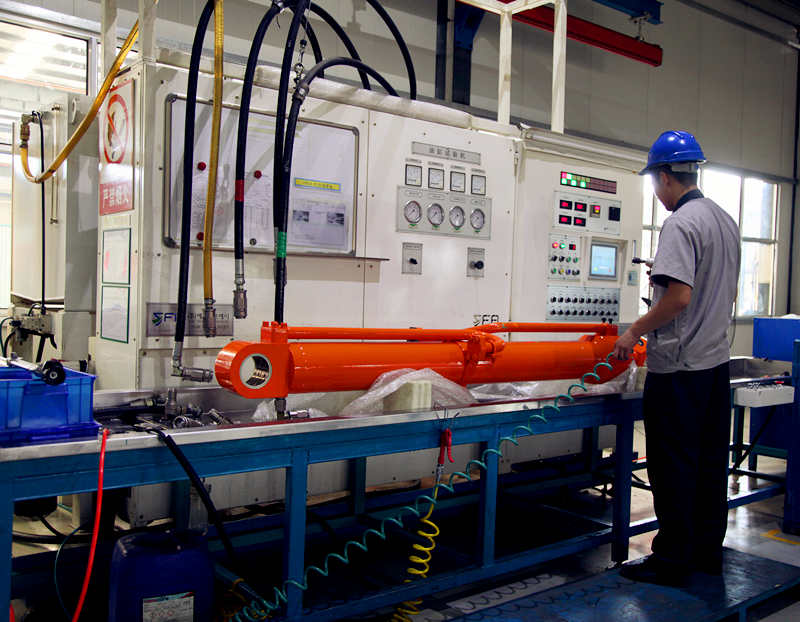

Conducting a proof test on hydraulic cylinders is fundamental in ensuring their efficacy and safety. A pivotal aspect of the manufacturing process entails verifying that each cylinder operates as intended. Prior to the application of paint and final dispatch to clients, a meticulous examination, also referred to as the proof test, is administered. This step is crucial, as it guarantees both the operational reliability and safety features of the cylinders. Our prior publications have underscored the significance of these components; given their status as vital safety elements within machinery, their flawless performance is imperative.

What happens in a proof test?

The basic instructions for a proof test step by step:

1.The cylinder is put to the test bench tightly and securely

2. Hoses are attached to the cylinder's oil connections or ports

3. Testing pressure is checked from the work order or from the customer's drawing

4. Worker tells the computer the cylinder's values (the values differ depending on the cylinder in question) → the computer starts the test

5. During the test, a cylinder makes a specified amount of strokes (as in back and forth motion) → this rinses the cylinder from the inside

6. After the movements have been carried out, the worker starts the actual proof test → the cylinder is first pushed with over pressure rod out and then rod in

7. During the proof test, the welds are inspected in case of any mistakes or leaks in welds or seals

8.After the proof test has successfully been carried out, the pressure is released from the cylinder

When a new product is being tested, a representative from our design department and a supervisor must be present throughout the whole testing sequence.

What might be detected in a proof test?

For example, problem with the welding : In this case, the cylinder needs to be dismantled and necessary repairs are done for the welds.

An internal leak :There might, for example, be a deviation or mistake in an internal surface which then breaks the cylinder's seals and causes an internal leak. An experienced worker spots the faults by carefully following the pressure levels: in case the pressure drops too fast, there is something wrong with the cylinder.

Transcending the mundane checklist, executing a flawless proof test is an art reserved for true professionals. At HCIC, we transform this seemingly straightforward task into a masterful display of expertise. Our engineers are meticulously trained to detect the slightest anomalies, ensuring each cylinder meets perfection.Embracing efficiency, when all is in order, our proof tests areswift and precise. Yet, our commitment to excellence extends beyond, as we relentlessly refine our processes in pursuit of unparalleled quality.

Unfolding the blueprint of precision, pressure specifications, and the intricacies of motion lie delicately detailed in each cylinder's design. Whether crafted by HCIC's visionary designers or tailored to our clients' unique specifications, every cylinder is a testament to collaborative ingenuity. We tailor the proof test to mirror our clients' exacting standards, empowering them to dictate the fate of the testing oil – retained or replaced, the choice is theirs.In the symphony of verification, documentation serves as the crescendo.

We meticulously compile test reports, harmoniously integrating HCIC's stringent standards with our clients' bespoke requirements. Once the proof test achieves its triumphant conclusion, the cylinders embark on their journey towards a coat of resilience, adorned with protective sheaths, courtesy of our diligent testers.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

KA

KA